|

|

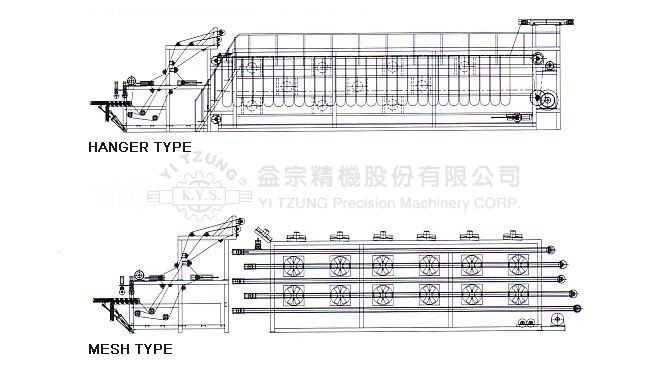

THE MAIN STRUCTURE OF MESH TYPE BATCH OFF MACHINE CONSISTS OF SHEET INLETSECTION, SHEET STORAGE SECTION AND SHEET OUTPUT SECTION.

| MODEL | BO-M500 | BO-M1000 |

| MAX SHEET WIDTH | 500 | 1000 |

| SHEET THICKNESS | 5-12 mm | 5-12 mm |

| MAX SHEET INLET SPEED | 30M/min(MAX) | 30M/min(MAX) |

| COOLING LAYER | 5 LAYERS | 5 LAYERS |

| DISTANCE BETWEEN COOLING LATER | 200~300mm | 200~300mm |

| TOTAL POWER | 14HP | 14HP |

| COOLING METHOD | WATER/AIR COOLING | WATER/AIR COOLING |

| POWER OF COOLING FAN | 0.5HP/1PC | 0.5HP/1PC |

| SHEET TEMP. AFTER COOLING (FOR REFERENCE) | < 40o | < 40o |

| DIMENSION | 12860(L)*1620(W)*3200(H) | 12860(L)*1900(W)*3200(H) |

Đánh giá

Chưa có đánh giá nào.